The SEL-451 Instruction Manual provides essential guidance for setup, installation, and operation. This comprehensive guide ensures efficient and safe use of the device.

Overview of the SEL-451 Protection, Automation, and Bay Control System

The SEL-451 is a versatile and robust protection, automation, and bay control system designed for substation automation. It offers advanced features like high-speed breaker control, customizable protection settings, and seamless communication capabilities. The system combines speed, flexibility, and reliability, making it ideal for complex power distribution applications. With support for multiple protection functions, including instantaneous and time-overcurrent settings, the SEL-451 ensures comprehensive fault detection and clearance. Its modular design allows for easy integration with existing systems, while its user-friendly interface simplifies configuration and monitoring. The SEL-451 is a standalone solution that enhances operational efficiency and ensures reliable power system performance.

Importance of the Instruction Manual for Proper Setup and Operation

The instruction manual is crucial for the correct installation, configuration, and operation of the SEL-451 system. It provides detailed guidelines to ensure safe and efficient setup, avoiding potential errors or system malfunctions. The manual includes essential information on pre-installation checks, communication protocols, and troubleshooting procedures. By following the manual, users can optimize system performance, ensure compliance with industry standards, and maintain reliability. It also highlights safety precautions and compliance requirements, making it an indispensable resource for technicians and operators to handle the SEL-451 effectively and responsibly.

Installation and Setup

Proper installation and setup of the SEL-451 are critical for its functionality. This section guides users through pre-installation checks, mounting, and initial powering of the device.

Pre-Installation Checks and Requirements

Before installing the SEL-451, ensure all environmental and electrical requirements are met. Verify the device is compatible with existing systems and power sources. Check for any firmware updates and ensure all necessary tools and documentation are available. Proper grounding and shielding are essential to prevent interference and ensure reliable operation. Additionally, review the manual for specific installation guidelines tailored to your setup. Adhering to these checks guarantees a smooth installation process and optimal performance of the SEL-451 Protection, Automation, and Bay Control System.

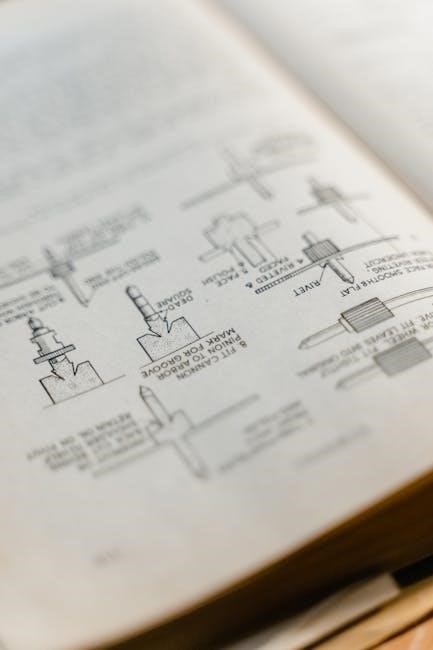

Mounting and Connecting the SEL-451 Relay

Mounting and connecting the SEL-451 Relay requires careful attention to ensure reliable operation. Use compatible enclosures and secure the relay with appropriate fasteners. Ensure proper wiring connections, following the manual’s guidelines for terminal assignments and torque specifications. Verify that all communication ports and power supplies are correctly linked. Avoid loose connections or incorrect wiring, as they may lead to malfunctions. Before powering up, double-check all connections for integrity. Proper mounting and wiring are critical for optimal performance and safety. Always consult the manual for specific installation requirements and torque values to ensure compliance with SEL’s standards.

Powering Up the Device and Initial Configuration

Powering up the SEL-451 Relay requires connecting it to a stable power supply within the specified voltage range. Ensure all connections are secure before applying power. Once powered, the device will perform a self-test. After the boot process, access the front panel or remote interface to begin initial configuration. Set basic parameters such as communication settings and protection logic according to the manual. Verify that all indicators function correctly and that the system is operational. Perform a test cycle to ensure proper functionality. Refer to the manual for detailed steps to complete the initial setup successfully.

Configuration and Programming

Configure communication settings and protection logic to meet specific requirements. Program control equations and customize protection functions for precise automation and control of the SEL-451 system.

Setting Communication Parameters and Protocols

To ensure seamless communication, configure the SEL-451 with appropriate protocols such as DNP3 or Modbus; Set baud rates, parity, and data formats to align with network requirements. Use the provided software tools to define IP addresses and ports for Ethernet connections. Properly configure serial ports for RS-232 or RS-485 communication. Enable encryption and authentication for secure data transmission. Refer to the manual for detailed steps on setting up communication parameters to integrate the relay into your SCADA system effectively. This ensures reliable data exchange and remote monitoring capabilities.

Configuring Protection Functions and Logic

Configure protection functions such as overcurrent, undervoltage, and directional elements to meet specific system requirements. Define thresholds, time delays, and sensitivity levels for accurate fault detection. Use control equations to customize logic for automation and interlocking schemes. Enable advanced features like synchrophasor measurement and power quality monitoring. Set up custom alarms and event logging to track system behavior. Ensure proper coordination with other relays and devices for reliable operation. Test configurations thoroughly to verify correct functionality and adjust settings as needed for optimal performance. Refer to the manual for detailed instructions on configuring protection logic and ensuring system-wide coordination. This ensures precise and reliable protection operation.

Operation and Control

The SEL-451 operates in Manual, Automatic, or Remote mode, ensuring flexibility in control. Switching modes is straightforward, with clear indicators for operational status and system responses.

Modes of Operation: Manual, Automatic, and Remote Control

The SEL-451 offers three primary operation modes: Manual, Automatic, and Remote Control. In Manual mode, users can directly control the relay through the faceplate interface. Automatic mode enables the relay to function based on predefined settings and logic, ensuring autonomous operation. Remote Control mode allows external systems or operators to manage the relay, enhancing flexibility for integrated control systems. Switching between modes is simple, with clear visual indicators. This versatility ensures the SEL-451 adapts to various operational needs, providing reliable performance across different control scenarios while maintaining user-friendly accessibility.

Understanding Alarm Points and Their Management

The SEL-451 relay features advanced alarm management, capable of displaying up to 66 alarm points. These alarms provide critical system status updates, ensuring timely response to operational changes. The relay automatically displays new alarms in both manual and autoscrolling modes, simplifying monitoring. Users can customize alarm messages and thresholds to suit specific applications. This robust system enhances situational awareness, allowing for proactive maintenance and issue resolution. Proper alarm management ensures reliable operation, minimizing downtime and optimizing system performance.

Troubleshooting and Maintenance

The SEL-451 relay includes diagnostic tools for identifying and resolving issues. Regular maintenance ensures optimal performance, with options for resetting and updating firmware as needed.

Diagnostics and Common Issues

The SEL-451 relay includes advanced diagnostic tools to identify and resolve issues efficiently. Common problems may include communication errors, misconfigured settings, or firmware inconsistencies. Users can access detailed alarm points, which provide insights into system anomalies. The relay automatically displays new alarms, aiding quick troubleshooting. For connectivity issues, checking protocol configurations and ensuring proper cable connections is essential. Firmware updates can often resolve software-related problems. Regular system restarts or resets may also clear transient faults. Refer to the manual for step-by-step guidance on addressing these issues and restoring optimal functionality. Proper diagnostics ensure reliable operation and minimize downtime in critical applications.

Resetting and Updating the SEL-451 Relay

Resetting and updating the SEL-451 relay ensures optimal performance and resolves potential issues. To reset, place the relay in manual mode and use the reset command. For updates, download the latest firmware from the SEL website. Follow the manual’s step-by-step instructions to avoid configuration loss. Regular updates enhance security and add features. Always back up settings before proceeding. Resetting restores default settings, while updates improve functionality. These processes are crucial for maintaining system reliability and ensuring compliance with industry standards. Proper execution prevents data loss and ensures uninterrupted operation. Regular maintenance prolongs the relay’s lifespan and ensures it operates efficiently in all conditions.

Safety Precautions and Compliance

The SEL-451 manual outlines critical safety precautions to ensure proper handling and operation. Adhere to warnings and cautions to prevent hazards and maintain compliance with industry standards.

Warnings and Cautions for Proper Handling

Proper handling of the SEL-451 requires adherence to specific warnings and cautions. Avoid applying lubricants to switches and ensure all connections are secure to prevent malfunctions. Always power down the device before maintenance to eliminate risks of electric shock. Use appropriate personal protective equipment (PPE) when working with high-voltage components. Follow installation guidelines strictly to avoid damage. Never modify the relay without authorization, as this may void warranties or compromise safety. Compliance with these precautions ensures optimal performance and operator safety, aligning with industry standards and regulations outlined in the manual. Failure to comply may result in equipment damage or personal injury.

Compliance with Industry Standards and Regulations

The SEL-451 is designed to meet rigorous industry standards, ensuring reliability and safety in various applications. It adheres to IEC and IEEE standards for protection and automation systems, guaranteeing compatibility and performance. The relay complies with FCC regulations, minimizing electromagnetic interference. Its design also aligns with environmental standards, ensuring durability in diverse operating conditions; Compliance with these standards is verified through extensive testing, providing users with a trusted solution for substation automation. By adhering to these regulations, the SEL-451 maintains high operational integrity, meeting the demands of modern power systems while safeguarding against potential hazards and ensuring adherence to global certification requirements.

Additional Resources and Support

Access official documentation, guides, and data sheets on the SEL website. Contact SEL support for assistance with setup, troubleshooting, and software updates.

Accessing Official Documentation and Guides

The SEL-451 Instruction Manual and related resources are available on the SEL website. Users can download PDF files, data sheets, and installation guides for comprehensive setup and operation details. The official documentation provides essential information for troubleshooting, configuration, and maintenance. Additionally, SEL offers literature, flyers, and configurable labels to support various applications. For specific queries, the manual can be accessed directly from the SEL website or through their customer support portal. Ensuring you refer to the latest version of the manual is crucial for proper device functionality and safety. Contacting SEL support directly is recommended for personalized assistance.

Contacting SEL Support for Assistance

For technical assistance with the SEL-451, users can contact SEL Support through their official website or support portal. The support team offers guidance on installation, configuration, and troubleshooting. Additionally, SEL provides resources like FAQs, forums, and contact forms for inquiries. Customers can also access phone support for urgent issues or schedule consultations with SEL engineers. Ensuring accurate and efficient problem resolution, SEL’s support services are tailored to meet user needs. Regular updates and maintenance tips are also available to help users optimize their SEL-451 system performance and compliance with industry standards. Contacting SEL Support is the recommended approach for resolving complex technical challenges.